Lo3-40 オゾン発生器滅菌器 40 グラム食品窒素発生器

説明

基礎情報

| 状態 | ノイ |

| 認証 | RoHS、UR、ISO、CE、CCC |

| 電圧 | 380V |

| 保証 | 1年 |

| タイプ | スキッドに取り付け/コンテナ化 |

| 純度 | 99-99,999% |

| コアコンポーネント | PLC、圧力容器、電磁弁、分子 |

| 顧客サービス | エンジニアは海外でも機械の修理が可能です。 |

| 窒素露点 | -40℃ |

| 寿命 | 10年 |

| 輸送パッケージ | 標準木箱/パレットの輸出 |

| 仕様 | 1000*1200*1500 |

| 商標 | LDH |

| 起源 | 北京、中国 |

| HSコード | 841960 |

| 生産能力 | 500 |

製品説明

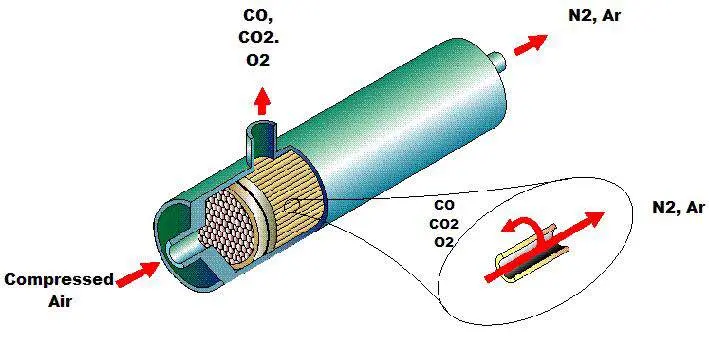

40m3/hの食品包装、特殊窒素機械、純度99.99% LDH GAS Systemsは、窒素製造、酸素製造、精製システムなどのオンサイトガスプラントを専門とする中国のメーカーです。 スキッドマウント上の高純度窒素用のコンパクトなシステム。 2017 年以来、世界中で 100 以上のシステムが構築されており、システムはその信頼性、費用対効果、利便性、そして優れたサービスであらゆる人々の尊敬を集めています。 LDH システムのファミリーは、化学および精製、石油およびガス生産、エレクトロニクス、航空および航空宇宙、製薬/ヘルスケア、食品、冶金、ガラス、石炭採掘および水産養殖など、さまざまな業界で使用されています。 LDHシステムは、最先端の技術と完璧な製造技術の融合を体現したものです。 当社の目標は、より信頼性が高く、経済的で便利な LDH 空気分離システムとより専門的なサービスをお客様に提供することです。 PSA 窒素発生装置の正式名称: Pressure Swing Adsorption (PSA)。 PSA は、1960 年代から 1970 年代初頭にかけて海外で急速に開発された新しいガス分離技術です。 その原理は、異なるガス分子の異なる「吸着性能」に基づいてモレキュラーシーブを使用してガス混合物を分離することです。 原料として空気を使用します。 空気中の窒素と酸素を、高効率かつ幅広い固体吸着剤で選択的に吸着して分離します。

現在、窒素と酸素の製造にはカーボンモレキュラーシーブとゼオライトモレキュラーシーブがより一般的に使用されています。 モレキュラーシーブによる酸素と窒素の分離は、主にモレキュラーシーブの表面での 2 つのガスの異なる拡散速度に基づいています。 カーボンモレキュラーシーブは、活性炭とモレキュラーシーブのいくつかの特性を備えた炭素ベースの吸着剤です。 カーボンモレキュラーシーブは、孔径が 0.3 nm ~ 1 nm の範囲の非常に小さな微細孔で構成されており、ガス (酸素) の直径が小さいほど、モレキュラーシーブの固相への拡散がより速く、より多く行われるため、炭素モレキュラーシーブ内の窒素が富化されます。気相を達成することができます。 一定の時間が経過すると、モレキュラーシーブは酸素吸着と平衡になり、異なるガスの吸着における異なる圧力下での炭素モレキュラーシーブに対応します。 吸着特性:圧力を下げて酸素吸着で炭素モレキュラーシーブを除去します。 このプロセスは再生と呼ばれます。 PSA は通常、2 つの塔を並列に使用し、加圧吸着と減圧再生を交互に行って窒素の連続流を取得します。

3) Spare Parts ServiceWorldwide, quick and low-priced over the complete lifetime of your plant. The distinct tagging of all plant components delivered by us enables us to identify clearly the spare parts requested by you. We supply you with products designed for a long life and economic efficiency. For modifications and extensions we look for the most optimal and economic solution for your individual purpose. 4) Maintenance/RevisionsRegular inspection and maintenance ensures permanent operation, avoids damage and prevents unexpected breakdowns. In the course of maintenance/revision works we check all relevant components for function and condition, exchange defect, used and worn parts and afterwards optimally eadjust your plant to the given operating conditions. Depending on the plant size and scope of work, our service range comprises also a detailed scheduling of revisions as well as coordination and supervision of contractors. As a matter of course we supply maintenance documentation in form of reports and spare part recommendations, and we coordinate our schedules according to your requirements. 5) TrainingKnow-how for your personnel. Operation, maintenance and repair, electric measuring and control equipment or process engineering - we offer you specific training by our experts. Whether on site working with theplant itself, or on our permises, we concentrate on your questions and problems. What is a Packaging Gas?Air contains approximately 78% nitrogen, 21% oxygen and a variable amount of moisture. When exposed to air, foods such as potato chips absorb moisture and go stale and soggy quickly. Atmospheric oxygen also reacts with the unsaturated fatty acids present in foods, resulting in rancid off-flavours. Consequently, it is always a challenge faced by food manufacturers in preserving the desirable quality and prolonging the shelf life of food products.The use of packaging gas is an effective solution. A packaging gas is a gas that is introduced into a package before, during or after filling with food to protect the food from oxidation or spoilage. Examples include nitrogen, carbon dioxide and nitrous oxide. Nitrogen has a long history of use as a packaging gas in various foods including snacks, breakfast cereals, candies, bakery products, dried fruits and vegetables, and processed meat products.Nitrogen Does More than a Packaging GasNitrogen has found its way to the brewery and coffee industries where nitrogen is infused in beer or cold brew coffee to make 'nitro beer' or 'nitro brew', giving the final product a richer and creamier mouthfeel.How does Nitrogen Work as a Packaging Gas?Unlike the air you breathe every second, nitrogen used in food packaging contains very little oxygen and moisture. Nitrogen is inert (i.e. not reacting with any food components), odourless and tasteless. When nitrogen is introduced into a package, it drives out oxygen and any moisture present. By modifying the atmosphere inside the package, food packaging with nitrogen preserves quality, slows down spoilage and extends the products' shelf life.Nitrogen also cushions and protects delicate foods inside the package from being crushed during handling. Nonetheless, the amount of nitrogen used should provide enough protection but not too much to allow space for additional expansion due to pressure changes in transit and during storage.The package, with low gas permeability, must be sealed tightly to prevent the nitrogen from escaping. Once you open the package, the food inside is exposed to atmospheric air containing oxygen and moisture. Without protection from an immediate, controlled environment, the contents are then prone to moisture pickup, spoilage and oxidation. Therefore, it is best to consume the food products as soon as possible once the package is opened.Food suppliers are always seeking ways to extend shelf life. Improved shelf life allows manufacturers to extend their geographical reach and allows the product to remain in stores and consumer's homes longer. Modified Atmosphere Packaging (MAP) is a technique commonly used in the food processing industry to extend shelf life. The MAP process involves displacing the air inside a package with a protective gas to keep oxygen at controlled levels (less than 2 percent). Too much oxygen and moisture in a package often leads to bacterial growth and oxidation resulting in spoilage, inconsistent flavors, poor product quality, and shortened shelf life. Nitrogen is frequently used as a protective gas because of its dry, inert qualitiesSources of nitrogenNitrogen can be obtained from outside suppliers in the form of high-pressure tanks, dewars, or bulk liquid supply. Nitrogen can also be produced on-site using standard compressed air with an in-house nitrogen generator. An in-house generator separates nitrogen and oxygen from the air, and can often be the most efficient and economical method of supplying nitrogen for MAP applications.Disadvantages of a delivered nitrogen supplyRelying on outside vendors can pose several challenges including uncontrollable price increases, contract negotiations, tank rental fees, adherence to OSHA requirements, hazardous material fees, delivery surcharges, and local and state taxes. Problems such as scheduling conflicts, delivery delays, and lengthy procurement processes can slow down operations.This all adds up to extra administrative work and higher operational costs. The delivery approach also doesn't fit the trend toward lean production techniques and developing fewer, more efficient supply chains. Precautions must also be taken when handling and storing high pressure cylinders. A dangerous situation can be created if a cylinder is dropped and a valve is broken off, potentially causing the cylinder to become a projectile.Operational benefits of generating nitrogen on-siteGenerating your own supply of nitrogen in-house eliminates the challenges associated with outside vendors and ensures long-term cost stability. Generating nitrogen in-house is also good for the environment and represents a sustainable approach to supplying the gas. Producing nitrogen off site at fractional distillation plants and transporting it to end users is energy intensive and can result in large amounts of CO2 emissions.

弊社の連絡先